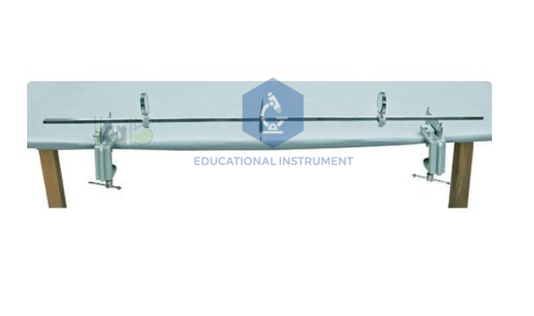

Bending of Beam Apparatus, Koenig’s Method

Product Code : SCL-MH-11925

The Bending of Beam Apparatus (Koenig’s Method) is engineered for the high-precision quantification of Young’s Modulus in University and Vocational physics curricula. It utilizes a dual-mirror optical lever system to resolve infinitesimal angular deflections, ensuring data accuracy superior to traditional mechanical spherometers. This Educational Instrument is compliant with ISO 9001:2015 manufacturing protocols for rigorous material science experimentation.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

Heavy-duty Cast Iron Pillar Supports; Machined Brass/Steel Test Beams |

|

Measurement Architecture |

Dual-Mirror Optical Lever (Koenig’s Method) |

|

Component Integrity |

Calibrated Knife Edges for Frictionless Pivot Points |

|

Dimensions |

Standard 1000mm Beam Length (Support spacing adjustable) |

|

ISO Compliance Code |

ISO 9001:2015 Accredited Facility |

|

HS Code |

9023.00.00 (Demonstrational instruments and apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Dual-Mirror Optical Configuration. -Outcome: Allows students to Analyze angular displacement through telescope observation, facilitating the calculation of radius of curvature in stressed beams.

Feature: Adjustable Knife Edge Supports. Outcome: Enables the Evaluation of beam deflection under varying span lengths, supporting empirical verification of the Euler-Bernoulli beam theory.

Feature: Standardized Loading Hanger. Outcome: Supports the Application of precise stress-strain mathematical models by providing a stable datum for slotted weight increments.

International Logistics & Compliance

To maintain the structural alignment and optical mirror integrity during intermodal transit, this Educational Instrument is secured in export-grade seaworthy crating (ISPM-15 compliant). Every consignment for international procurement includes the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification, and User Manuals in English. The Tropicalized design is tested for operation up to 45°C and 90% Humidity, ensuring that the metallic beams and mirror coatings remain resistant to oxidation and atmospheric degradation.

Why Source from the OEM?

Procuring from the Educational Instrument OEM ensures total vertical integration, from the precision machining of the knife edges to the final calibration of the optical lever mirrors. Unlike third-party traders, our facility utilizes batch-tested for uniformity protocols, ensuring that the metallurgical properties of the test beams remain consistent across high-volume institutional deployments. Sourcing directly guarantees direct factory spares availability—including replacement mirrors and calibrated beams—providing a validated maintenance path for international TVET development tenders and government educational supply chains.