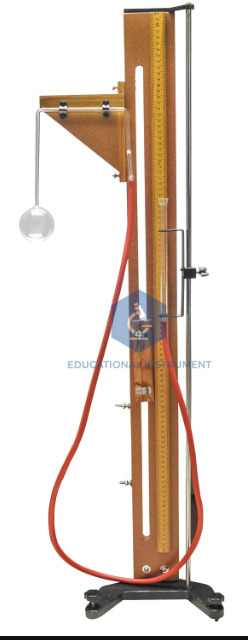

Charles Law Apparatus (Combined)

Product Code : SCL-PLE-11814

Engineered for the empirical verification of the direct proportionality between gas volume and absolute temperature, this Charles’ Law Apparatus Combined fulfills ISO 9001:2015 quality benchmarks. Designed for University and TVET thermodynamics curricula, it facilitates high-accuracy data acquisition for constant pressure environments using calibrated borosilicate components and integrated thermal monitoring systems.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

Borosilicate 3.3 Expansion Glass / Heavy-duty Powder-Coated Metal |

|

Scale Graduation |

Linear metric scale with 1mm resolution for volumetric tracking |

|

Pressure Configuration |

Integrated U-tube design for Isobaric (Constant Pressure) monitoring |

|

Thermal Range |

Optimized for ambient to 100°C via integrated heating jacket compatibility |

|

Mounting |

Rigid vertical support rods on a stable, vibration-dampening base |

|

ISO Compliance Code |

ISO 9001:2015 Manufacturing Protocols |

|

HS Code |

90230090 (Instruments, apparatus and models for demonstrational purposes) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Calibrated U-tube Manometer.Outcome: Enables learners to verify isobaric conditions through manual leveling, facilitating the Analysis of pressure-volume-temperature relationships.

Feature: Borosilicate Heating Jacket. -Outcome: Provides visual clarity of the expansion process under varying thermal gradients, supporting the experimental Validation of absolute zero extrapolation.

Feature: Integrated Metric Scale. -Outcome: Supports high-precision data logging for quantitative graphing and linear regression, essential for Evaluating gas law constants in Thermodynamics Module 202.

International Logistics & Compliance

All units are secured in export-grade seaworthy crating (ISPM-15 compliant) to mitigate vibration-induced fractures during multi-modal transit. Technical documentation provided includes the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification (on request), and comprehensive User Manuals in English. The instrument features a tropicalized design, stress-tested for continuous operation in environments up to 45°C and 90% relative humidity, ensuring longevity in varied geographical deployments.

Why Source from the OEM

Direct procurement from the factory ensures total vertical integration, from in-house glass blowing to the final precision calibration of the manometer assembly. Our batch-tested uniformity eliminates the measurement variability common in decentralized trading supplies. Choosing the OEM guarantees direct factory spares availability and a dedicated technical support pipeline, ensuring maximum laboratory uptime and full compliance with sovereign educational tender requirements.

.jpg)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpg)