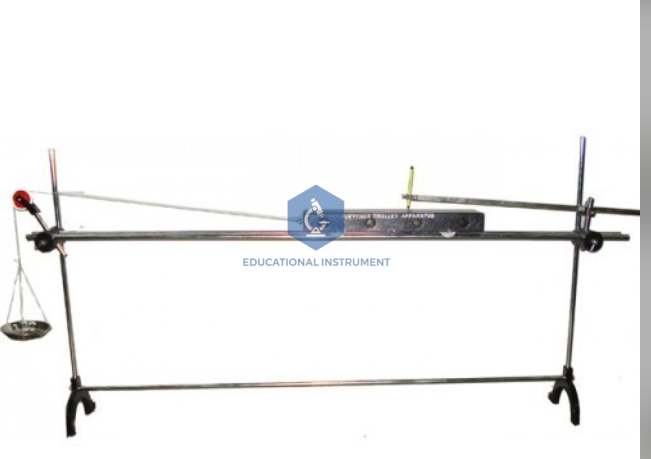

Fletcher Trolley

Product Code : SCL-MH-11931

The Fletcher Trolley Apparatus is a high-precision instrument for the empirical verification of Newton’s Second Law and the quantification of linear acceleration. Engineered for University, Secondary, and Vocational (TVET) physics curricula, it enables high-fidelity data recording via an integrated frequency-stabilized oscillating marker. This Educational Instrument is manufactured under ISO 9001:2015 protocols to ensure repeatable results in friction-compensated environments.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

Seasoned Hardwood (Kiln-Dried) or Anodized Aluminum Profile |

|

Recording Mechanism |

Integrated Oscillating Brush/Pen with 6V DC or Clockwork Drive |

|

Track Dimensions |

1500mm x 100mm (Standardized for Bench-Scale Lab Use) |

|

Bearing Type |

Low-Friction Precision Stainless Steel Axle Bearings |

|

ISO Compliance Code |

ISO 9001:2015 Quality Management System |

|

HS Code |

9023.00 (Demonstrational instruments and apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Frequency-Stabilized Oscillating Marker. Outcome: Allows students to calculate instantaneous velocity and acceleration by analyzing displacement patterns on paper strips, supporting Analysis of motion-time graphs.

Feature: Precision-Machined Low-Friction Wheels. Outcome: Minimizes resistive forces during data acquisition, enabling students to Evaluate the difference between idealized kinematic equations and empirical laboratory results.

Feature: Integrated Mass-Hanger and Pulley System. -Outcome: Facilitates the Application of constant force variables to verify the proportionality of force and acceleration in accordance with $F=ma$.

International Logistics & Compliance

To ensure the calibration of the oscillating unit and the structural integrity of the track during intermodal transit, this system is secured in export-grade seaworthy crating (ISPM-15 compliant). Comprehensive documentation provided for international procurement officers includes the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification, and technical User Manuals in English. The Tropicalized design is validated for operational stability in environments reaching 45°C and 90% Humidity, ensuring the track remains warp-resistant and metallic components remain oxidation-free.

Why Source from the OEM?

Procuring from the Educational Instrument OEM ensures total vertical integration, from the in-house seasoning of timber to the precision assembly of the frequency-driven recording units. Unlike third-party traders, our facility utilizes batch-tested for uniformity protocols, ensuring that friction coefficients and vibration frequencies remain consistent across large institutional cohorts. Sourcing directly guarantees direct factory spares availability—including replacement marking pens, recording rolls, and motor assemblies—providing a validated maintenance path for international development tenders and government educational supply chains.