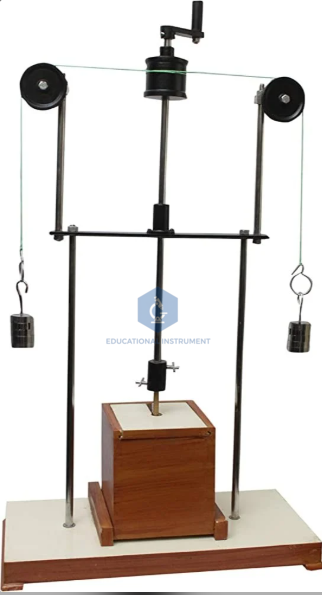

Joule's Mechanical Heat Experiment Apparatus

Product Code : SCL-MH-11974

Engineered for quantitative analysis of thermal conductivity in low-conductance materials (e.g., glass, ebonite, rubber), this educational instrument utilizes the steady-state Lee’s Disc method.1 Designed for University and Advanced Vocational Physics curricula, it facilitates high-precision heat transfer experiments compliant with ASTM E1225-standard logic. The apparatus supports rigorous pedagogical modeling of Newton’s Law of Cooling and Fourier’s Law in controlled laboratory environments.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Steam Chamber Material |

Polished Copper or Heavy-Gauge Brass |

|

Base Disc Material |

High-Thermal Mass Polished Brass |

|

Base Disc Dimensions |

Diameter: 110mm; Thickness: 10mm–12mm |

|

Support System |

Tri-point suspension via non-conductive silk/synthetic cord |

|

Mounting |

Robust cast-iron retort stand with rectangular stable base |

|

Thermal Access |

Dual radial ports for 6mm diameter 0.1°C resolution thermometers |

|

Working Fluids |

Saturated Steam or High-Temperature Thermal Oil |

|

HS Code |

90230090 (Educational/Demonstrational Apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Dual-Disc Interface. Outcome: Enables students to establish a measurable temperature gradient across poor conductors, supporting Advanced Thermodynamics Module 202.

Feature: Polished High-Emissivity Surfaces.2 Outcome: Allows for the empirical calculation of heat loss through radiation and convection, facilitating the application of Newton’s Law of Cooling.

Feature: Suspended Base Design. Outcome: Minimizes conductive heat leakage to the environment, ensuring students achieve a high-fidelity steady-state equilibrium for accurate "k" value derivation.

Feature: Integrated Radial Thermometer Ports. Outcome: Students observe real-time thermal stabilization, enhancing data logging skills and graphical analysis of cooling curves.

International Logistics & Compliance

This educational instrument is prepared for global distribution via export-grade seaworthy crating (ISPM-15 compliant timber) to prevent transit damage to the precision-machined brass surfaces. Each unit is supplied with a comprehensive Manufacturer’s Authorization Form (MAF), optional IQ/OQ/PQ certification for institutional quality audits, and technical manuals in English. The tropicalized design is verified for long-term stability in high-humidity laboratory environments up to 90% RH.

Why Source from the OEM?

Procuring directly ensures vertical integration of the manufacturing process, from in-house metallurgical casting to precision lathe-finishing of the disc surfaces. Unlike generalist traders, the OEM maintains strict batch-tested uniformity, ensuring that the mass and specific heat of the brass components are calibrated to a standard tolerance. Direct sourcing guarantees factory-level technical support and the immediate availability of spares, including replacement steam chambers and precision-drilled brass slabs.