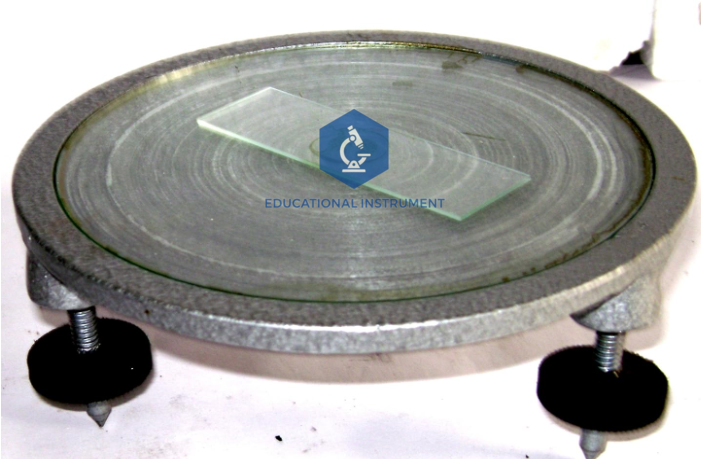

Quincke's Surface Tension Apparatus

Product Code : SCL-MH-11957

Engineered for the empirical determination of surface tension and contact angle of non-wetting liquids via the sessile drop method. This apparatus facilitates high-precision height-to-diameter ratio measurements required for advanced fluid mechanics and material science modules. Optimized for University and Research-level laboratories, it supports rigorous experimental data collection in alignment with international metrology standards.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Primary Base Construction |

Heavy-duty, vibration-damped metallic frame with leveling adjustment |

|

Material Grade (Plate) |

Optically flat glass plate, stress-relieved for uniform surface energy |

|

Adjustment Mechanism |

Triple-point leveling screws for precise horizontal alignment |

|

Containment System |

Chemical-resistant trough optimized for mercury or high-density fluids |

|

Measurement Interface |

Compatible with standard 0.01mm resolution travelling microscopes |

|

ISO Compliance Code |

Manufactured under ISO 9001:2015 Quality Management Systems |

|

HS Code |

9023.00 (Instruments, apparatus and models, designed for demonstrational purposes) |

Key Pedagogical Outcomes

Feature: Optically Flat Glass Interface. Outcome: Ensures uniform surface interface for the measurement of sessile drops, supporting Advanced Fluid Mechanics Module 202.

Feature: Integrated Triple-Point Leveling. Outcome: Eliminates gravitational bias in drop formation, facilitating accurate calculation of contact angles and Laplace pressure.

Feature: Heavy-Duty Mercury-Compatible Trough. Outcome: Enables the study of non-wetting liquid dynamics and cohesive forces in condensed matter physics.

Feature: Scalable Measurement Path. -Outcome: Allows students to utilize vernier-based height analysis to derive surface tension (γ) values, reinforcing error analysis protocols.

International Logistics & Compliance

As a specialized OEM, we ensure all units are prepared for global distribution via export-grade, seaworthy crating (ISPM-15 compliant) to prevent transit-induced calibration shifts. Every shipment includes a Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification guidelines, and comprehensive technical manuals in English. The apparatus features a tropicalized design, utilizing corrosion-resistant coatings tested for sustained operation in environments reaching 45°C and 90% humidity.

Why Source from the OEM?

Procurement through our vertically integrated facility eliminates the inconsistencies associated with third-party trading. Our in-house manufacturing process includes precision grinding of optical components and batch-testing for structural uniformity. By maintaining direct control over the machining and assembly stages, we guarantee factory-direct spares availability and long-term technical support, ensuring the instrument remains a functional asset within the institutional inventory for multi-decade lifecycles.

.jpg)

.jpg)