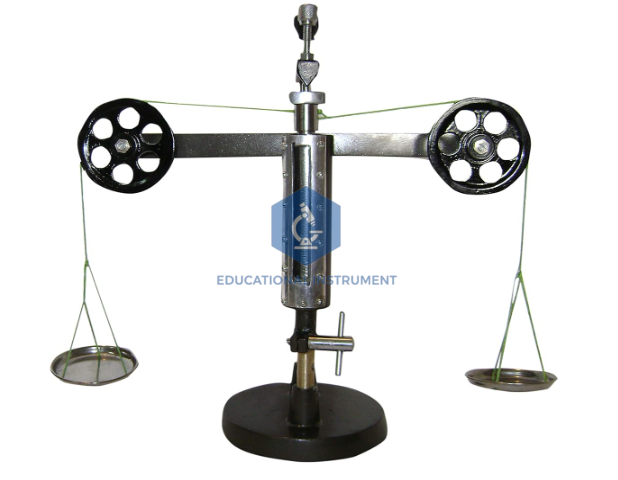

Viscometer Searle's Pattern

Product Code : SCL-MH-11961

Engineered for the quantitative determination of dynamic viscosity in Newtonian fluids, this Searle’s Pattern Viscometer is calibrated for advanced undergraduate and vocational physics curricula. It facilitates precise fluid friction measurements via rotational torque, adhering to international educational standards for rheological analysis. Ideal for higher education laboratories requiring durable, repeatable experimental setups for high-viscosity liquid assessment.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Operational Mechanism |

Coaxial cylinder rotational torque system |

|

Material Grade |

Heavy-duty cast iron base; corrosion-resistant alloy cylinders |

|

Base Configuration |

Tripod base with integrated leveling screws for axial alignment |

|

Measurement Interface |

Integrated circular scale with 360° graduation |

|

Torque Application |

Dual-pulley friction-compensated system with weight pan |

|

Thermal Monitoring |

Dedicated thermometer mounting bracket for temperature-viscosity correlation |

|

HS Code |

9027.80 (Instruments and apparatus for measuring viscosity) |

|

ISO Compliance |

Manufactured under ISO 9001:2015 Quality Management Systems |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Dual-cylinder coaxial design.

Outcome: Facilitates the empirical study of laminar flow and shear stress between concentric surfaces, supporting Fluid Mechanics Module 202.

Feature: Integrated scale and weight-pan assembly.

Outcome: Enables students to calculate the relationship between applied torque and angular velocity, reinforcing concepts of rotational dynamics.

Feature: Transparent/Removable outer vessel.

Outcome: Allows for visual verification of fluid levels and air-bubble elimination, ensuring data integrity during high-viscosity testing.

Feature: Precision-machined friction-compensated pulleys.

Outcome: Minimizes mechanical resistance variables, allowing learners to isolate and measure fluid-specific drag coefficients accurately.

International Logistics & Compliance

This educational instrument is prepared for global distribution via export-grade seaworthy crating (ISPM-15 compliant) to prevent transit damage. Standard procurement documentation includes the Manufacturer’s Authorization Form (MAF), optional IQ/OQ/PQ Certification for institutional audits, and comprehensive technical manuals in English. The unit features a tropicalized, powder-coated finish tested for operational stability in environments up to 45°C and 90% humidity, ensuring longevity in diverse geographical climates.

Why Source from the OEM?

Sourcing directly ensures full vertical integration of the manufacturing process, from the precision machining of the inner rotor to the final batch-testing for uniformity. Unlike third-party traders, we provide direct factory spares availability and long-term technical support. Our in-house calibration protocols ensure that every unit meets the mechanical tolerances required for repeatable scientific data in academic research and laboratory instructio