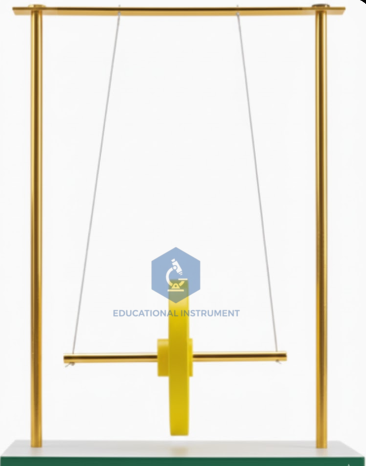

Maxwell Wheel

Product Code : SCL-MH-11944

The Maxwell Wheel is a precision-engineered instrument designed for the empirical validation of the Law of Conservation of Energy and rotational inertia.1 Engineered for University, Advanced Secondary, and Vocational TVET curricula, it facilitates the quantitative analysis of potential-to-kinetic energy conversion.2 The apparatus is calibrated to meet rigorous institutional standards for mechanics and dynamics laboratory modules.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Flywheel Construction |

Precision-machined high-density Metal/Alloy (130mm Diameter) |

|

Axle Configuration |

Centralized rigid steel axle with integrated suspension eyelets |

|

Suspension System |

High-tensile, low-stretch nylon cords (Adjustable length up to 800mm) |

|

Support Structure |

Stable, heavy-duty metallic frame with anti-slip base |

|

Operational Dimension |

Approx. 450mm (H) x 150mm (W) x 420mm (L) |

|

ISO Compliance Code |

ISO 9001:2015 Manufacturing Standards |

|

HS Code |

9023.00 (Instruments and apparatus for demonstrational purposes) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Energy Transition Quantification: Outcome: Allows students to calculate the conversion of gravitational potential energy into translational and rotational kinetic energy, supporting Mathematical Application of classical mechanics.

Moment of Inertia Determination: Outcome: Facilitates the Analysis of flywheel geometry and mass distribution to derive rotational inertia constants ($I$).

Momentum Reversal Observation: Outcome: Provides a visual reference for nearly-elastic collisions at the lowest point of descent, enabling students to Evaluate the effects of jerk and linear momentum reversal.

Friction and Damping Study: Outcome: Enables the Measurement of energy dissipation over multiple oscillation cycles to assess non-conservative forces in mechanical systems.

International Logistics & Compliance

Our export protocols are optimized for high-volume international tenders and Ministry of Education (MoE) bulk procurements.

Packaging: Every unit is secured in export-grade seaworthy crating (ISPM-15 compliant) to ensure structural integrity during maritime transit.

Documentation: Consignments are accompanied by a Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ certification, and comprehensive technical manuals in English.

Durability: The hardware features a tropicalized, corrosion-resistant coating, laboratory-tested for performance in high-humidity environments up to 45°C/90% RH.

Why Source from the OEM?

Procuring directly from the factory eliminates the middleman-induced "trader" perception and ensures vertical integration of product quality. Unlike generic suppliers, we maintain in-house metallurgical control over the flywheel's mass distribution to ensure axial symmetry and minimal vibration. Every batch is tested for uniformity and concentricity, ensuring that laboratory data remains repeatable across different workstations. Furthermore, we provide direct factory spares availability, including calibrated replacement suspension cords and axle assemblies, ensuring the long-term lifecycle of the educational assets.

.jpg)