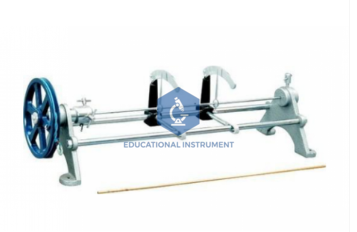

Torsion Apparatus Searle's Type

Product Code : SCL-MH-11946

This Searle’s Type Torsion Apparatus is engineered for the empirical determination of the modulus of rigidity in cylindrical specimens through statical torsion methods. Designed for University and Vocational Engineering laboratories, it facilitates high-precision angular displacement measurements under varying torque loads. The unit complies with international metrological standards for material stress analysis and laboratory-grade mechanical testing.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Chassis Construction |

Heavy-duty cast iron base with dual-pillar support frame |

|

Torsion Wheel Diameter |

150mm - 200mm (Calibrated circular scale) |

|

Angular Measurement |

0-360° Scale with integrated Vernier reading to 0.1° |

|

Material Grade |

High-tensile steel frame; Brass/Steel specimen wires |

|

Clamping Mechanism |

Precision-machined split-chuck collets for zero-slip interface |

|

Specimen Compatibility |

Cylindrical rods up to 5mm diameter |

|

ISO Compliance Code |

ISO 9001:2015 Manufacturing Standards |

|

HS Code |

9023.00.10 (Technical Instructional Apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Large-Diameter Calibrated Torsion Wheel. Outcome: Enables students to Apply torque calculations with high resolution, reducing percentage error in shear stress derivations.

Feature: Dual Split-Chuck Mounting System. Outcome: Allows learners to Analyze the impact of boundary conditions and effective length on the torsional rigidity of different alloys.

Feature: Integrated Vernier Scale. Outcome: Facilitates the Evaluation of minute angular deformations, supporting the verification of Hooke’s Law in shear.

Feature: Friction-Reduced Ball Bearing Support. Outcome: Ensures students can Evaluate theoretical vs. actual results by minimizing parasitic mechanical losses during data acquisition.

International Logistics & Compliance

As a specialized manufacturer for global educational tenders, we ensure all consignments utilize export-grade seaworthy crating (ISPM-15 compliant) to prevent structural misalignment during transit. Comprehensive documentation is provided for customs and institutional audit, including the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification, and localized technical manuals in English. The apparatus features a tropicalized finish—utilizing powder-coated cast iron and corrosion-resistant alloys—tested for operational stability in environments up to 45°C and 90% humidity.

Why Source from the OEM?

Procuring directly from the OEM ensures vertical integration and technical accountability. Our facility manages in-house metallurgical testing and precision machining of the torsion assemblies, ensuring batch-tested uniformity across all units. Unlike generalist traders, we provide direct factory spares availability, including calibrated specimen sets and replacement Vernier assemblies. Our mechanical engineering division maintains strict control over the casting and calibration processes, ensuring that the critical alignment between the torsion wheel and clamping chucks meets ISO laboratory tolerances.