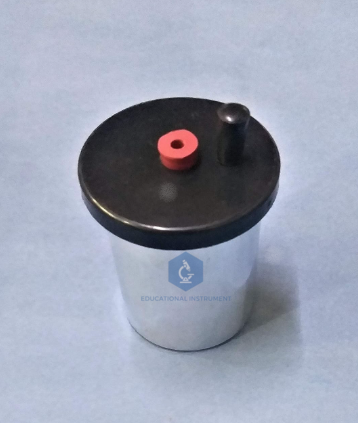

Copper Calorimeter

Product Code : SCL-MH-11973

This industrial-grade copper calorimeter is engineered for high-precision thermal capacity measurement and heat exchange verification. Developed for secondary and vocational STEM curricula, the unit ensures repeatable quantitative data in thermodynamics modules. It facilitates standardized experimentation for specific heat capacity determination, meeting institutional laboratory requirements for durability and thermal sensitivity in academic environments.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

High-Purity Spun Copper (Electrolytic Grade) |

|

Dimensions (Standard) |

75mm x 50mm (Height x Diameter) |

|

Dimensions (Large) |

100mm x 75mm (Height x Diameter) |

|

Construction Method |

Seamless Spun Copper with Parallel Walls |

|

Surface Finish |

Polished, Oxidation-Resistant Coating |

|

ISO Compliance Code |

ISO 9001:2015 Manufacturing Standard |

|

HS Code |

9023.00.00 (Educational Instruments and Apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: High-Purity Spun Copper Vessel. Outcome: Minimizes thermal lag during heat transfer, enabling students to Analyze specific heat capacity with low experimental error margins.

Feature: Parallel-Wall Cylindrical Design. Outcome: Facilitates uniform agitation via integrated stirrers, allowing learners to Evaluate thermodynamic equilibrium in liquid mixtures.

Feature: Standardized Geometric Volumes. Outcome: Supports curriculum-aligned Application of the Method of Mixtures, ensuring consistent results across multiple student laboratory stations.

International Logistics & Compliance

Consignments are secured in export-grade seaworthy crating (ISPM-15 compliant) to ensure structural integrity during multi-modal transit. Essential documentation, including the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification protocols, and technical User Manuals in English, is provided to streamline institutional compliance and asset tagging. The vessel features a tropicalized finish, laboratory-tested for oxidation resistance and structural stability in environments reaching 45°C and 90% humidity, ensuring long-term utility in diverse geographical laboratory zones.

Why Source from the OEM?

Direct procurement leverages vertical integration, from precision copper spinning and metal finishing to final assembly and calibration. Unlike third-party traders, the OEM ensures batch-tested uniformity and material traceability. This manufacturing control provides direct factory spares availability—including vessels, lids, and matching copper stirrers—minimizing laboratory downtime and optimizing the Total Cost of Ownership (TCO) for government and private institutional tenders.