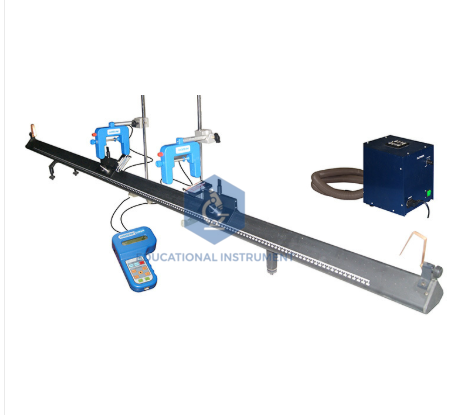

Air Track Apparatus

Product Code : SCL-MH-11923

The Linear Air Track Apparatus is a high-precision kinematics system engineered for the empirical verification of classical mechanics in University, Secondary, and Vocational (TVET) laboratories. It resolves friction-related data skewing in linear motion experiments, ensuring high-fidelity results in momentum and acceleration modules. This Educational Instrument is compliant with ISO 9001:2015 quality standards for rigorous institutional procurement.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

High-Tensile Anodized Aluminum Alloy (Triangular Profile) |

|

Effective Track Length |

2000 mm (Standard) |

|

Surface Finish |

Precision-machined with high-density air-exit orifices |

|

Scale Graduation |

Dual-sided millimetric scale (1 mm resolution) |

|

ISO Compliance Code |

ISO 9001:2015 Quality Management System |

|

HS Code |

9023.00.00 (Demonstrational instruments and apparatus) |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

Feature: Perforated Air Cushion Interface. Outcome: Negates mechanical friction to near-zero levels, allowing students to Evaluate Newtonian laws of motion in an idealized environment.

Feature: Interchangeable Glider Attachments. Outcome: Facilitates the Analysis of elastic and inelastic collisions, supporting the quantification of kinetic energy transfer and momentum conservation.

Feature: Integrated Three-Point Leveling System. Outcome: Promotes the Application of precision calibration techniques, requiring students to establish a perfect horizontal datum before data acquisition.

International Logistics & Compliance

To ensure the structural integrity of the aluminum extrusion during intermodal transit, this Educational Instrument is secured in export-grade seaworthy crating (ISPM-15 compliant). Every consignment includes a comprehensive documentation package: the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification, and technical User Manuals in English. The Tropicalized design is validated for operational stability in environments reaching 45°C and 90% Humidity, preventing oxidation of the anodized surfaces and ensuring longevity in diverse climates.

Why Source from the OEM?

Procuring from the Educational Instrument OEM ensures total vertical integration, from in-house precision extrusion of the track profiles to the final calibration of the airflow distribution. Unlike third-party traders, our facility utilizes batch-tested for uniformity protocols, ensuring that air pressure remains constant across the entire track length. Direct sourcing guarantees direct factory spares availability—including gliders, springs, and air-supply hoses—providing a validated lifecycle path for international government tenders and institutional supply chains.