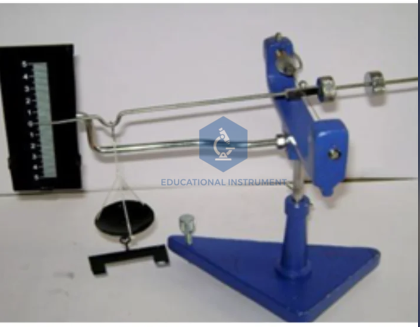

Searle's Surface Tension Balance

Product Code : SCL-MH-11960

This precision-engineered apparatus is designed for the quantitative determination of liquid surface tension using the force-balance principle. Engineered for University and Vocational higher education, it enables the measurement of the downward pull exerted on a solid surface in contact with a fluid. It facilitates experimental adherence to fundamental fluid mechanics curricula and calibrated material characterization protocols.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Primary Beam Construction |

High-tensile steel or plated brass horizontal beam |

|

Pivot Mechanism |

Hardened steel or agate knife-edge bearings for low-friction oscillation |

|

Base Material |

Heavy-duty, vibration-damped cast iron with anti-corrosive powder coating |

|

Adjustment System |

Integrated leveling screws with a plumb line for orthogonal alignment |

|

Measurement Components |

Optically flat glass plate (vane) and light-weight aluminum scale pan |

|

ISO Compliance Code |

Manufactured under ISO 9001:2015 Quality Management Systems |

|

HS Code |

9023.00 (Instruments, apparatus and models, designed for demonstrational purposes) |

Key Pedagogical Outcomes

Feature: Agate/Hardened Steel Knife Edges. -> Outcome: Provides a low-friction fulcrum for precise null-point detection, supporting Advanced Mechanics and Metrology modules.

Feature: Adjustable Leveling Screws and Plumb Line. Outcome: Ensures the frame is perfectly orthogonal to the gravitational vector, teaching students the necessity of spatial alignment in experimental physics.

Feature: Calibrated Vane/Glass Plate Interface. Outcome: Facilitates the calculation of surface tension ($\gamma$) by measuring force over a known perimeter, reinforcing Fluid Dynamics and Molecular Physics principles.

Feature: Integrated Weight Pan and Fractional Weights. Outcome: Develops foundational laboratory skills in balance calibration and mass-to-force conversion via the $F = mg$ relationship.

International Logistics & Compliance

As a specialized Educational Instrument OEM, we ensure all units are prepared for global distribution via export-grade seaworthy crating (ISPM-15 compliant) to prevent structural misalignment during transit. Documentation provided with every consignment includes the Manufacturer’s Authorization Form (MAF), IQ/OQ/PQ Certification guidelines, and comprehensive Technical Manuals in English. The apparatus features a tropicalized design, utilizing stabilized alloys and coatings tested for sustained operation in laboratory environments reaching 45°C and 90% humidity.

Why Source from the OEM?

Procurement through our vertically integrated facility ensures the geometric precision of the knife-edge pivots and the linear calibration of the balance beam—critical factors often compromised by third-party traders. Our in-house machining and batch-tested assembly processes guarantee uniform sensitivity across all units. By maintaining direct factory control, we provide immediate spares availability (vanes, pans, and weights) and specialized technical support, ensuring the instrument remains a functional institutional asset for multi-decade lifecycles.

.jpg)

.jpg)